|

| July 08, 2014 | Volume 10 Issue 26 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Army developing 'compound sensors' to guide munitions in absence of GPS

By Timothy Rider, The U.S. Army Armament Research, Development and Engineering Center (ARDEC)

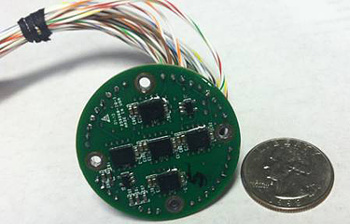

An example of an Army compound sensor array next to a quarter to reflect relative size.

When preparing to face a more talented opponent, coaches tell their players that the path to victory is pulling together as a team to somehow obtain more than a sum of each player's talents.

For Army scientists, that same concept may have been expressed in the form of an advanced algorithm that gets optimum performance from a team of inertial sensors, which could be used to guide cannon-fired munitions to a target with near precision, even without Global Positioning Satellite (GPS) navigation.

In addition to high performance, a big advantage to the team of sensors is greatly reduced cost.

The scientists were able to make 10 ordinary, automotive-grade inertial sensors work together to perform "orders of magnitude" better with the algorithm, matching the performance of a missile-grade inertial sensor, said Christopher Stout, assistant product officer for affordable precision technologies at Picatinny Arsenal in Rockaway Township, NJ.

The accuracy of each of the 10 sensors can be measured on the order of 1/300th of a gravitational unit, or "G." The 10 sensors with the algorithm can improve the accuracy obtained by an order of magnitude. Also, while the sensor comprised of 10 automotive-grade sensors costs $100, the missile-grade sensor is significantly larger, heavier, and costs more than $3,000.

The key is in the algorithmic approach developed by ARL that does more than obtain an average of each sensor's contributions.

"That algorithm that is used is so complex it makes my head spin," Stout said.

"The algorithm takes into account the multi-dimensional relationships between each of the six data measurements from each individual sensor as well as the relations between each of the 10 sensors onboard," explained Stout.

The algorithm can recognize if one sensor is flawed and eliminate its outputs from the final computations. It can also recognize if one sensor is consistently giving a high or low reading and then adjust the output so that all the sensors contribute to an overall higher performance, according to Stout.

The combination of the inertial sensor's accuracy, small size, and affordability may contribute to its one day being used to guide cannon-fired munitions to a target with near precision even if GPS navigation technology is unavailable, according to Stout.

The scientists and engineers are developing low-cost, next-generation precision-guided munitions while working from two U.S. Army Research Development and Engineering Command laboratories. Stout is working with three others at Picatinny's Armament Research Development and Engineering Center to develop the hardware and prepare the prototypes for testing.

Four team members from Army Research Laboratory at Aberdeen Proving Ground, MD, wrote the algorithm and continue to be involved in software development.

Next-generation precision technologies aim to use guidance technologies that will function if GPS navigational data is absent, either because of a glitch or because an enemy has somehow disabled it, according to a briefing by the team.

Currently, fielded precision-guided munitions leverage GPS navigational technology to determine a round's location during flight. Using the location information, computers in the round impart instructions to steering surfaces that guide a round through the air to a predetermined target.

"Inertial guidance works in GPS-denied environments," Stout said. "If you know where you started, you can use inertial guidance to determine a location in flight."

Inertial guidance uses sensors (accelerometers and gyroscopes) that measure changes in an object's speed, direction, and rotation. A computer calculates position with a clock and data from the sensors.

Inertial technologies have spread prolifically in the commercial marketplace due to their uses in automobiles and smartphones, according to Stout. That availability contributes to lowered cost; however, the accuracy of the commercially available sensors is unsuitable to attain functionally precise munitions.

In order to work effectively in guided weapons, an inertial sensor must be very accurate because computers will "grow" any error during the more than 60-second flight time of a projectile.

"It's a compounding problem," Stout said.

Data from simulations, high-G survivability, and sensor characterization tests strengthens the notion that a projectile with the compound sensors, like the team has prototyped, would have accuracy close to current GPS-guided rounds.

U.S. munitions using GPS technology include the 155-mm M982 Excalibur and 155-mm rounds with a Precision Guidance Kit. The guidance provides a precision capability that allows U.S. troops to avoid collateral damage.

For example, a PGK round corrects the ballistic trajectory of the conventional projectile to improve the round's accuracy to less than 50 m Circular Error Probable (CEP).

Fifty meters CEP means that if you drew a circle around a target at 50-m radius, the rounds have to fall inside the circle 50 percent of the time.

Excalibur rounds attain a CEP of better than 10 m. By comparison, conventional artillery rounds have an accuracy of about 270 m CEP at maximum ranges.

While a prototype circuit card assembly with the low-cost inertial guidance technology has been tested at Picatinny Arsenal's Soft Catch and Recovery System to verify its durability, it has yet to be tested in a way that includes other influencing factors that would be present during actual military operations.

Stout is working with his team in New Jersey and Maryland to develop the round for its next step, a flight test in an "operationally relevant" environment.

The team's concept is that inertial guidance technology could be inserted as an enhancement to an existing GPS-guided round, Stout explained.

According to the concept, if GPS is not available after being fired, the round would then leverage inertial guidance, which would guide the round to the target.

Both teams are also developing other technologies that may further contribute to developing precision accuracy in "GPS denied" environments, including technologies that make in-flight corrections by comparing satellite terrain imagery with imagery obtained by the round.

If the test is successful, Stout believes the technology may be appealing to a product manager for a precision-guided round.

"Both labs are trying to maintain well-defined roles so we don't duplicate efforts, but we leverage our strengths," said Stout. "We'd like to have a successful flight test by the end of the year."

ARDEC is part of the U.S. Army Research, Development and Engineering Command, which has the mission to develop technology and engineering solutions for America's Soldiers.

Published July 2014

Rate this article

View our terms of use and privacy policy